We are expanding our material

know-how and test services

with the DEKRA laboratories!

Accredited test laboratory

to DIN EN ISO/IEC 17025.

Your specialist for metals,

plastics, elastomers.

Hardness testing of metals and plastics.

Hardness is the mechanical resistance that a material opposes to the mechanical penetration of a harder, softer or equally hard test specimen. Depending on the type of action, a distinction is made between different types of hardness.

The hardness test is an indispensable step in the quality assurance of a product within the various stages of the manufacturing process. Various test methods are available for testing the hardness of metals and plastics. Which hardness test method is suitable for your project depends, among other things, on the material to be measured.

All hardness testing methods have a common basic principle:

A standardized test body – for example a diamond pyramid and diamond cone or hard metal ball – is pressed onto the surface of the material. Then the surface or the penetration depth of a test body is measured.

Hardness is often a good indicator of the tensile and wear properties of a material.

The definition of hardness differs from that of strength.

This represents the resistance of a material to deformation.

The hardness, along with strength, ductility, rigidity, fracture toughness, density and melting temperature, is one of the material properties.

Hardness testing of metals

Brinell hardness test (HB):

- DIN EN ISO 6506-1 – Metallic materials / Brinell hardness test / Part 1: Test method

- ASTM E10 – Standard test method for Brinell hardness of metallic materials

In the Brinell hardness test, a hard metal ball (tungsten carbide) with a specific ball diameter is pressed vertically into the surface of a specimen as an indenter under a defined force. We use the Brinell hardness test to check the hardness of ferrous and non-ferrous materials. However, the Brinell hardness test can only be used to test the hardness of soft to medium-hard workpieces.

Rockwell hardness test (HR):

- DIN EN ISO 6508-1 – Metallic materials / Rockwell hardness test / Part 1: Test method

- ASTM E18 – Standard test method for Rockwell hardness of metallic materials

In contrast to the hardness testing methods according to Brinell and Vickers, the Rockwell hardness of a material results from the penetration depth of an indenter (diamond cone) when a certain pre- and test force is applied.

This hardness test is used to check the hardness properties of ferrous materials, especially in the hardened state.

The test body is preloaded with a specified test force into the surface of the workpiece to be tested. The depth of penetration of the test specimen at preload serves as the reference plane. The indenter is then subjected to the main load for a period of at least two and a maximum of six seconds. This is then removed again so that only the preload is effective.

The measure of the Rockwell hardness of the material is the difference between the indentation depths before and after application of the main load. The Rockwell units are calculated from the indentation depth. The indentation depth of the specimen is determined with a dial gauge connected to the test probe.

Vickers hardness test (HV):

- DIN EN ISO 2639 – Steel / Determination and testing of case hardening depth

- DIN EN 10328 – Iron and steel / Determination of hardening depth after surface hardening

- DIN EN ISO 18203 – Steel / Determination of the thickness of hardened surface layers

- DIN EN ISO 6507-1 – Metallic materials / Vickers hardness test – Part 1: Test method

- ASTM E92 – Standard test method for Vickers hardness of metallic materials

In Vickers hardness testing (Vickers hardness), a diamond pyramid with a square base and a dihedral angle of 136° is pressed vertically into the specimen under a defined force. The hardness measurement is used for testing the hardness properties of all metals.

Vickers hardness measurement is particularly suitable for measurement with low test forces for thin and small parts, such as coatings or workpieces with surface treatment.

Knoop hardness test (HK):

- DIN EN ISO 4545-1 – Metallic materials / Knoop hardness test / Part 1: Test method

- ASTM E384 – Standard test methods for Knoop and Vickers hardness of materials

Hardness testing of elastomers and plastics

- Shore-A hardness test according to ISO 868 – Determination of indentation hardness with a durometer (Shore hardness)

- Shore-D hardness test according to ISO 868 – determination of indentation hardness with a durometer (Shore hardness)

- IRHD – hardness test according to ISO 48 – rubber, vulcanized or thermoplastic / determination of hardness (hardness between 10 IRHD and 100 IRHD)

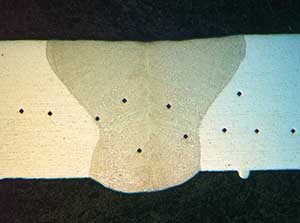

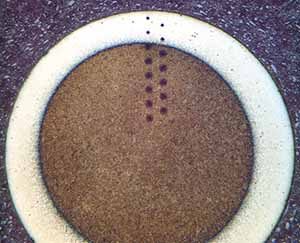

Hardness progression test in a rivet bolt