We are expanding

our material know-how

and test services with

the DEKRA laboratories!

Find out more in our

press release.

News:

Titanium alloys and titanium purity of medical instruments and implants according to

test laboratory

for materials testing, product testing & failure analysis.

Your specialist for metals,

plastics, elastomers.

We are expanding

our material know-how

and test services with

the DEKRA laboratories!

Find out more in our

press release.

News:

Titanium alloys and titanium purity of medical instruments and implants

according to DIN EN ISO 832

Accredited test laboratory

to DIN EN ISO / IEC 17025.

Your specialist for metals,

plastics, elastomers.

Compression test - bending test.

From the point of view of the direction of force, the compression test is the reverse of the tensile test. It is mainly used to determine the flow curves of brittle building materials (concrete, polymer concrete, bricks, wood, foams, etc.), packaging materials (e.g. cardboard, foams) and metals (e.g. cast iron) and is used to assess the material behavior under uniaxial compressive stress, whereby right-angled prisms, cylinders or tubes can be used as test specimens.

Our services at a glance:

- Pressure test on the component

- Compression test according to DIN EN ISO 604 (plastics in general)

- Bending properties according to DIN 50106 (metals)

- Flexural strength according to DIN EN ISO 178 (plastics) / 3-point / 4-point bending test

- Bending test (Dynstat) according to DIN 53435 (plastics) / 2-point bending test

- DIN EN ISO 7438 – Metallic materials / Bending test

- ASTM B 312 – Standard test method for green strength of specimens compacted from metal powders

- DIN EN ISO 148-1 – Metallic materials / Charpy notched bar impact test

Pressure test according to DIN EN ISO 604

To investigate the compression deformation behavior of test specimens under an external uniaxial compression load and to determine compressive strength, compressive modulus of elasticity and other aspects of the compressive stress-compression relationship, we use DIN EN ISO 604 for

– Rigid and semi-rigid thermoplastic injection and extrusion molding compounds, including filled and reinforced molding compounds

– Rigid and semi-rigid thermoset molding compounds, including filled and reinforced molding compounds and thermotropic liquid-crystalline polymers.

Flexural properties according to DIN 50106

This standard applies to the pressure test on all metallic materials and is used to assess the strength and deformation behavior of the material under investigation.

Flexural strength according to DIN EN ISO 178

The bending test according to DIN EN ISO 178 is used in particular to test brittle materials that cause metrological problems in tensile tests due to their failure behavior.

The principle of the bending test consists in the use of a two-part bending device in which the test specimen is clamped as a bending beam between two outer supports and loaded via one (3-point) or two (4-point) internal supports. It is tested at a constant speed until failure or until a specified deformation is reached, with the force applied and the deflection being measured.

Bending test according to DIN 53435 (Dynstat)

The bending test according to DIN 53435 (Dynstat) is used to characterize material properties in components made of plastic.

There are different types of bending tests, the sequence of which is similar and which differ in the type of specimen storage and the number of load applications. Various material parameters as well as the stress-strain curve of the bending stress can be determined from the recorded bending force and deflection values.

In the 2-point bending test, the test specimen is clamped at one end and loaded with a test stamp on the exposed side.

Examples of compression and bending tests

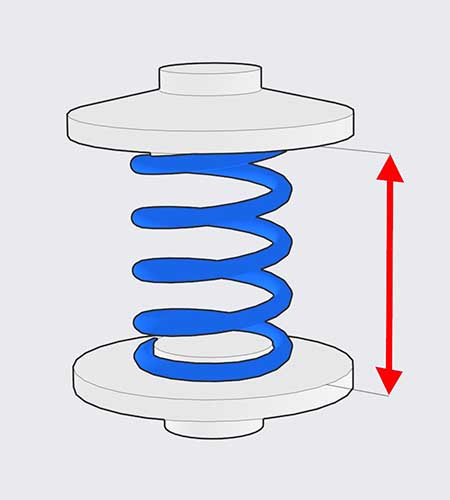

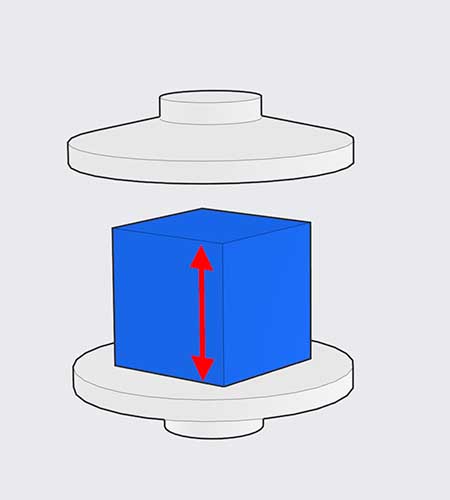

Pressure test on a standard sample (DIN 50106)

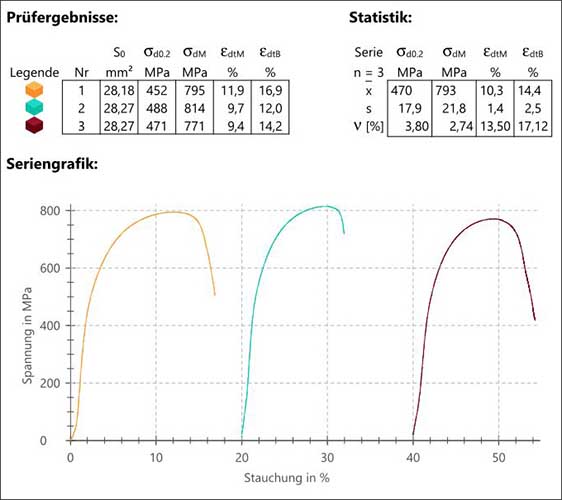

Graphic evaluation of the pressure test

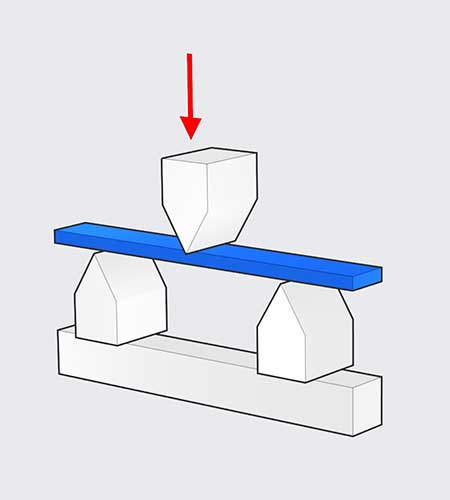

Pressure test on the component (source: Zwick)

3-point bending test (source: Zwick)