Erfahren Sie mehr in unserer

Presseinformation.

Akkreditiertes Prüflabor

nach DIN EN ISO/IEC 17025.

Ihr Spezialist für Metalle,

Kunststoffe, Elastomere.

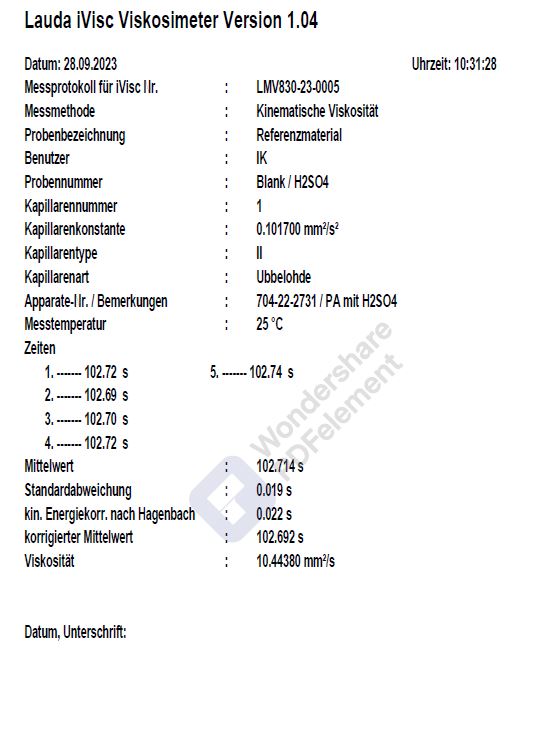

Determination of the viscosity number - Analysis of the flow properties of plastics

The viscosity number is an important parameter for evaluating the molecular weight distribution and material quality of polymer materials. In plastics analysis, it provides information on processability, ageing, thermal damage and suitability for recycling. The determination is carried out according to internationally recognized standards and is a proven method for quality assurance, incoming goods inspection and process control in plastics processing.

Our test procedures at a glance:

At DEKRA Kunststofflabor Bretten (formerly K-Labor) we offer the determination of the viscosity number or relative solution viscosity for the following materials:

- Polyamide (PA) in accordance with DIN 53727 and DIN EN ISO 307

- Polycarbonate (PC) in accordance with DIN 7744-2 and ISO 1628-4

- Polymethyl methacrylate (PMMA) in accordance with ISO 1628-6

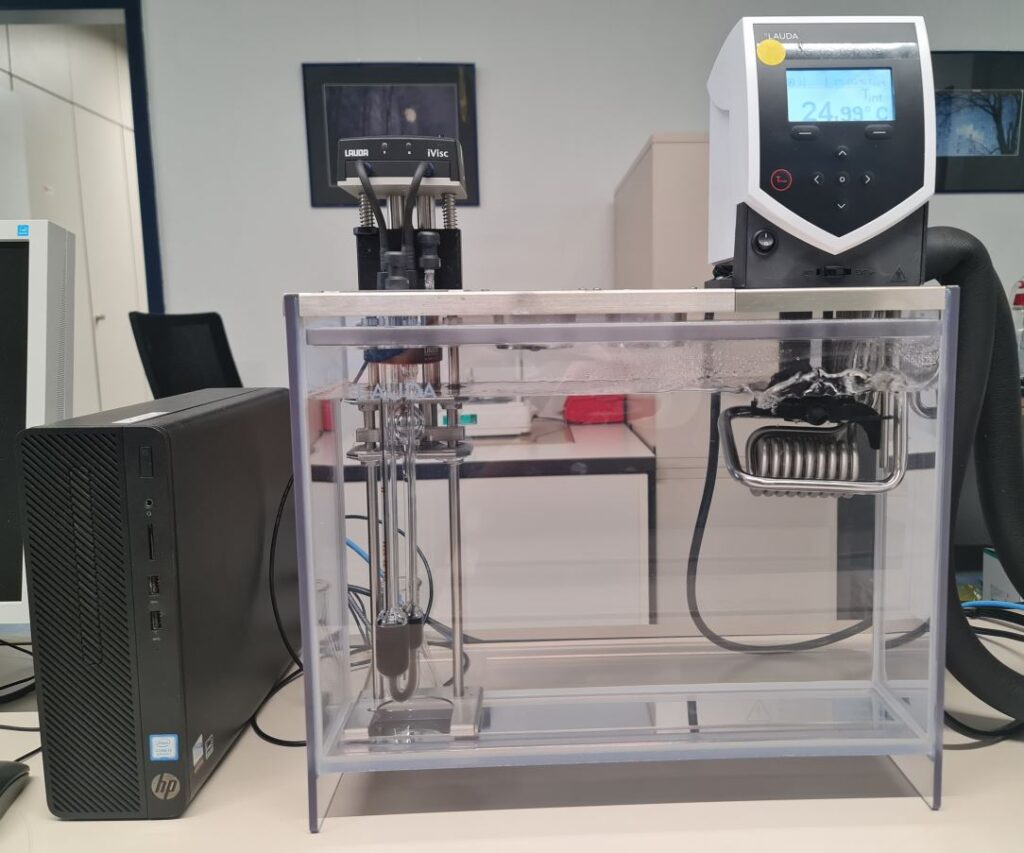

Plastic samples are dissolved in specific solvents and measured in Ubbelohde viscometers under defined conditions.

Typical areas of application for viscosity analysis

- Quality assessment of recyclates:

The viscosity number allows conclusions to be drawn about the degradation and suitability of recyclates for high-quality applications. This allows material batches to be specifically sorted and reusability to be improved.

- Monitoring of injection molding processes:

Deviations in the viscosity number can indicate thermal damage or fluctuations in the polymerization reaction. Regular analysis allows production parameters to be adjusted and rejects to be avoided.

- Incoming goods inspection of plastic pellets:

Before further processing, we check your granulate or regrind delivery for conformity with the required specifications – an essential basis for consistently high product quality.

- Material development and comparison of batches:

Especially when developing new compounds or comparing original material and recyclates, the viscosity number serves as a reliable criterion.

Advantages for our customers

- Early detection of material defects – avoid failures caused by unsuitable granulate or degraded recyclates

- Documented quality – ensure reliable test reports for your customers or internal QA

- Process optimization – adjust your injection moulding parameters or extrusion processes based on reliable data

- Compliance with standard specifications – especially for safety-relevant components or regulated markets (e.g. automotive, medical, electrical)

Your contact for viscosity analyses

Our laboratory in Bretten near Karlsruhe is your competent partner for testing polymer materials. Thanks to standardized procedures and many years of experience, we provide you with fast and reliable results – whether as part of an individual test, series monitoring or product development.